产品别名 |

污水处理,工业废水设备 |

面向地区 |

品牌 |

天通 |

|

规格 |

其它 |

加工定制 |

是 |

800t/d大豆制油工程废水处理工程实例

某饲料集团有限公司800t/d大豆 工程为日处理大豆800t,年生产日300d,年产油脂4万t。大豆制油生产工艺主要有预榨、浸出和炼油三个阶段

该项目主要废水来自于浸出和炼油两个工段。由于炼油车间所排放的油脚、废渣量较大,废水温度也较高,影响后续的生化处理,所以本废水处理工程采用浮与生化结合处理的工艺,气浮用以去除浮油和废渣,同时兼有降温效果。

一 设计水质水量及处理要求

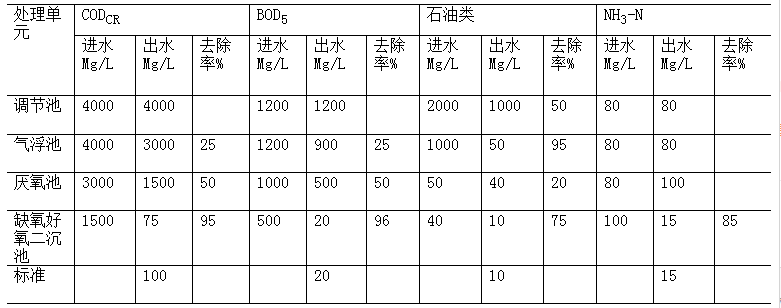

依据厂里提供的数据和实测资料,设计水量为200m³/d。进水水质为pH值6~9,CODCR≤4000mg/L,BOD5≤1200mg/L,动植物油 ≤2000mg/L,NH3-N≤80mg/L。

处理出水标准为《污水综合排放标准》(GB8988-1996)中标准,即pH值6~9, CODCR≤100mg/L,BOD5≤20mg/L,动植物油 ≤10mg/L,NH3-N≤15mg/L,SS≤70mg/L。

二 污水处理工艺流程

1 工艺流程

根据处理的废水水量、水质及处理要求,结合实验结果,认为水洗粗品后废水需经过预处理才能够进一步处理

2 工艺流程说明

废水从厂区经格栅自流到调节池,调节池内设污水泵。将废水提升到气浮池,废水经气浮池去除浮油、浮渣后,自流到厌氧池。废水经厌氧菌分解后,重力自流至缺氧池。缺氧池为主要反硝化除氮反应器,废水经过缺氧池后自流至好氧池。好氧池是生化处理的主体构筑物,废水在好氧菌的作用下去除大部分CODCR和BOD5,而后自流至二沉池泥水分离。上清液计量后外排。二沉池污泥部分回流至缺氧池,气浮产生的浮油、浮渣和剩余污泥经污泥酸化池酸化后外运用作肥料。为提高本工艺的脱氮效果,在缺氧池和好氧池之间增设内循环工艺,确保出水氨氮指标合格。

废水温度说明:实地调查表明,综合废水进入调节池之前水温为55~58℃,经调节池停留冷却后出水温度为43~45℃,经气浮池气浮处理后水温将至40℃一下,能满足后续生化处理对温度的要求。

An example of 800t/d soybean oil engineering wastewater treatment project

The 800t/d soybean project of one feed group co., LTD. Is the daily processing soybean 800t, the annual production day 300d, the annual production of oil 40,000 t. The process of soybean oil production mainly includes three stages: prepress, leaching and refining

The main waste water from the project comes from leaching and refining. Due to emissions from oil refining plant, oil foot, slag quantity is larger, waste water temperature is higher, affect the subsequent biochemical treatment, so the wastewater treatment engineering combined with biochemical treatment process is introduced and the air flotation to remove oil and waste residue, cooling effect concurrently at the same time.

Design water quality water and processing requirements

According to the data provided by the factory and the measured data, the design water amount is 200 meters cubed/d. The water quality of water is pH value of 6~ 9, CODCR is less than 4000mg/L, BOD5 is less than 1200mg/L, animal and vegetable oil is less than 2000mg/L, nh3-n is less than 80mg/L.

The standard of water discharge (gb8988-1996) is the first class standard of the sewage comprehensive discharge standard (gb8988-1996), namely, the pH value of 6~9, CODCR is less than 100mg/L, BOD5 is less than 20mg/L, and animal and vegetable oil is less than 10mg/L, nh3-n is less than 15mg/L, and SS is less than 70mg/L.

Sewage treatment process

1 process flow

According to the water quantity, water quality and treatment requirements of the treatment, combined with the experimental results, it is considered that the wastewater needs to be pretreated before it can be processed further

2 process description

The waste water flows from the gate of the factory to the regulating pool, and the sewerage pump is installed in the regulating tank. When the waste water is raised to the gas float pool, the waste water and gas tank can be used to remove the oil and scum and then flow to the oxygen tank. After the waste water is decomposed by anaerobic bacteria, gravity flows into anoxic pool. The anoxic pool is the main denitrification and nitrogen removal reactor, and the waste water is flowing to the oxygen tank after oxygen tank. Aerobic pool is the main structure of biochemical treatment, and the wastewater is used to remove most of the CODCR and BOD5, and then flow to the sink of the two sinks. The upper cleaning liquid is measured in the outside row. The sludge partially returned to the hypoxia pool, and the floating oil, scum and residual sludge produced by the gas flotation were used as fertilizer after acidification of sludge acidification. In order to improve the denitrification effect of this process, an internal cycle process was added between the oxygen-oxygen pool and the oxygen-oxygen tank to ensure that the ammonia nitrogen was qualified.

Description: waste water temperature field survey shows that comprehensive wastewater into regulating pool before the water temperature is 55 ~ 58 ℃, after adjusting pool for cooling water temperature is 43 ~ 45 ℃, bullishness of air-flotation treatment after the water will float pool to 40 ℃, can meet the requirements of the subsequent biochemical treatment of temperature.

Main construction, structure and design parameters

1 grille well

Planar size 1.0m x 2.0m, total depth of 1.0 m, underground brick mix structure, interior grid row.

2 adjust pool

HRT13.5 h, V = 112.5 m after effectively, plane size 6.0 m * 7.5 m, and the effective depth of 2.5 m, the total depth of 3.2 m, with separation tank, plane size 1.0 m * 7.5 m, and the effective depth of 2.5 m, underground reinforced concrete structure, a sewage pump 2 sets, 1 in 1 case.

3 gas float pool

Size 10 t/h, the effects to the site condition, adopt steel structure integration equipment, placed on the YanYangChi cover plate, shape dimension (L * W * h) = 4000 m by 2000 m by 1900 m, the gas-liquid mix pump, save dissolving tank and air compressor, save floor.

4 glass steel shed

FRP tent covers an area of 15 ㎡, built in gas float above the pool.

5 YanYangChi

HRT54h, V effective =450m cubed, plane size 6.0m x 18.5 m, effective depth of 4.3 m, total depth of 4.6m, internal packing, set backflow pump one, ground reinforced concrete structure.

6 anoxic pool

HRT22.5 h, V effective =187.5m cubed, plane size 6.0m x 7.5 m, effective depth of 4.3 m, total depth of 4.6 m, internal water mixer, ground reinforced concrete structure. Build with anaerobic pool.

7 aerobic pool

HRT22.5 h, V effective =187.5m cubed, plane size 6.0m x 7.5 m, effective depth of 4.3 m, total depth of 4.6 m, internal new ring perforated aeration pipe, ground reinforced concrete structure. Build with anoxic pool.

8 the second pond

HRT2.5 h, surface load rate from 0.7 m after / ㎡ h., plane size 3.5 m * 3.5 m, total 4.6 m deep, reinforced concrete structure on the ground, and aerobic pool's viability.

9 sludge acidizing tank

Floating oil, scum and residual sludge are connected to the acidification pond. The effective volume is 35 cubic meters. After the sludge is acidified, it is used to pump, transport and fertilizer regularly. The plane size 2.5m x 3.5m, effective water depth of 4.6 m, reinforced concrete structure, and two - sink pool.

10 comprehensive room

Flat size 7.5m x 4.0 m, equipped with wind machine room, distribution room and operation room.

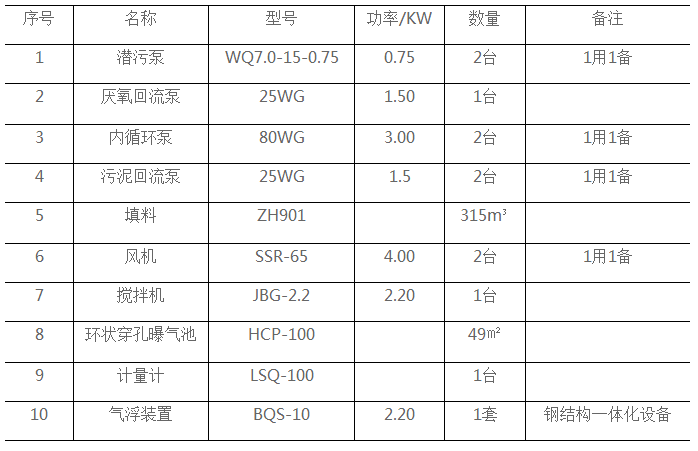

四 主要设备见下图

主要设备表

五 处理效果

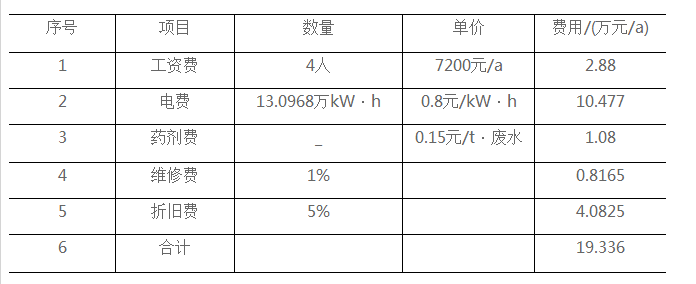

工程总投资81.6万元,废水处理成本见下表

工程总投资81.6万元,废水处理成本见下表

本废水处理工程年运行费用为19.336万元,年直接运行费用14.437万元,单位处理成本为2.69元/m³废水,单位直接处理成本为2.01元/m³废水。

济宁天通设备公司是国内的水处理设备研发、生产制造销售与一体的生产厂家,其核心产品以:污水处理设备、废水处理设备、工业废水设备、生活污水处理设备、食品厂污水处理设备、屠宰场厂废水处理设备、医院废水处理、制药厂废水设备等水处理设备为主;

济宁 天通,始终坚持以“先做人,后做事”为核心价值观,以“儒商文化”为品牌文化,以“做今日品牌,创企业”为宗旨,以“实用为本、德行天下”为理念,铸造中国机械行业的品牌。公司依托与国外的分支机构、国内的办事处、及的施工队伍,凭借行业内设备研发团队的强大创新能力、扎实的设备品质、完善的售后服务体系,赢得了客户的信任与合作。